‘Meating’ Processing Needs in Rural Minnesota

10 Aug 2022

News

As meat processing plants throughout the nation closed or curtailed production during the COVID-19 pandemic, farmers and suppliers turned to smaller, local processors as outlets for their animals. But after decades of being pushed out by the big processors, there simply were not enough to meet the demand. Officials in Minnesota have been researching possibilities to expand capacity but have run across a glaring weakness.

“The number one response from meat processors across the state on how to expand capacity was to hire more cutters,” said Stu Lourey, Government Relations Director with Minnesota Farmers Union. “But there is an incredible lack of trained persons to hire.”

Central Lakes College (CLC) is addressing that situation this fall with a new Meat Cutting and Butchery program at its Staples campus, one of two hands-on programs starting in response to COVID-19. The program will include 16-course credits in one semester, covering topics like Meat Cutting, Value-Added Processing and Internship in Meat Cutting and Butchery, preparing students for careers as meat carvers, butcher apprentices, food science technicians, meat processors and cutters and more. CLC has accepted 19 students to the program for the fall semester who will take the courses in evening classes and plan to offer the same format in the spring semester. The instructor is Jess Feierabend, who comes to CLC from the Baxter Costco, where he was the lead meat cutter for ten years and is an experienced custom butcher.

Extreme need

The COVID-19 pandemic exacerbated an already tenuous situation. Per USDA data presented in a 2018 report, four large conglomerates controlled 85% of the country’s beef market, compared to 25% in 1977. The same companies held 70% of the pork market, up from 33% in 1976 and 54% of the poultry markets, up from 35% in 1986. In addition to driving profits down for farmers, workers and rural communities, the significant control presented supply-side risks if any of the four companies faced major production setbacks, precisely what occurred in March 2020. Many large plants and processors scaled back operations or temporarily closed with the spread of COVID-19. By May 2020, daily capacity at U.S. cattle and hog facilities declined as much as 45%.

Those conditions prompted officials across the country to look for options to promote small businesses in the meat processing industry. When Dave Endicott began as CLC’s Dean of Staples Campuses in July 2020, he was tasked with exploring the possibility of a meat cutting and butchery program. His initial exploration focused on the retail side with grocers, but the existence of a glaring need on the agriculture side quickly became apparent.

“Small businesses like local butcher shops have not been able to compete for the past 20 years, forcing many to close down,” he said. “We must build that capacity again and provide opportunities for locally-raised food production systems instead of funneling so much to the big corporations.”

Mobile processing system

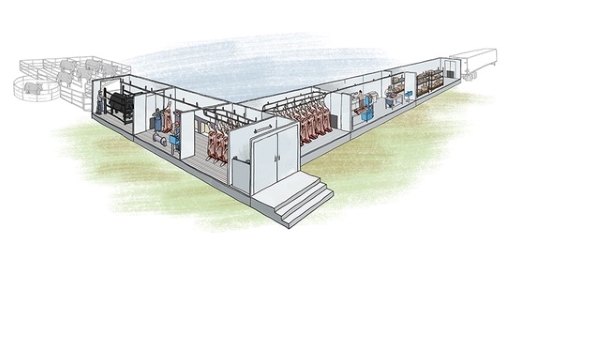

CLC’s students will have access to a state-of-the-art, USDA-certified mobile processing system to develop their skills. Farmers Union Foundation is purchasing mobile meat slaughtering and processing equipment for approximately $4 million. The funding came from a $2.9 million U.S. EDA grant and matching funds from the Agricultural Utilization Research Institute, Happy Dancing Turtle and the Farmers Union Foundation.

CLC’s students will have access to a state-of-the-art, USDA-certified mobile processing system to develop their skills. Farmers Union Foundation is purchasing mobile meat slaughtering and processing equipment for approximately $4 million. The funding came from a $2.9 million U.S. EDA grant and matching funds from the Agricultural Utilization Research Institute, Happy Dancing Turtle and the Farmers Union Foundation.

The first portion of the system will be a mobile slaughter trailer large enough to be pulled by a tractor from one community to another. The second is several modular systems to be utilized for chilling, aging and cut and wrap instruction on-site at CLC. The third aspect would be a stationary modular system to be kept in one community location yet-to-be-determined to serve as a forum for apprenticeships. Farmers Union will own the system.

“I am confident this will be the finest facility in the country for meat training,” said Endicott.

The business community has responded very favorably to the program. The UFCW Grocery Workers Union plans to provide opportunities for students to move into apprenticeships after they complete the course. Cub Foods in Baxter and Brainerd will provide their meat counters for student training until the modular systems are delivered.

Exciting progress

Lourey said it has been exciting to witness the excitement and energy of developing the program, but the question naturally led to procuring student interest as it progressed. That's where Rural Minnesota CEP stepped in.

“Rural Minnesota CEP offered its services to connect with its clients to build a pipeline of students to build a network that will promote longevity of the program,” Loury said. “I believe this is the first step to rebuild an industry that will serve rural Minnesota well.”

“Rural Minnesota CEP offered its services to connect with its clients to build a pipeline of students to build a network that will promote longevity of the program,” Loury said. “I believe this is the first step to rebuild an industry that will serve rural Minnesota well.”

Gaining student interest began with educating potential enrollees on the career possibilities, as agriculture leaders and grocers say they struggle to fill their positions. Many aging small business owners of local meat lockers and butcher shops are looking to sell but cannot find someone to buy their business. Therefore, shifting production toward local processors is not as simple as training new employees.

“Most think it's all hard work and no pay, but with a little time and the right training, there are real opportunities to earn $80,000,” said Endicott. “The reality is there is a good living to be made as a skilled meat cutter, not to mention the business possibilities for those with an entrepreneurial mindset.”

“Many processors currently in small businesses in rural communities are looking to retire soon, so the workforce challenge is developing more skilled workers and finding ways to retain what is currently present,” said Lourey.

To meet the challenge, CLC plans to develop a second semester for the program, moving into specialized meats, smoked sausages and more. In addition, the school would like to add a curriculum that deals with entrepreneurial and business development skills.

More Topics